Understanding the Art of Tube Bending at AWC Industries

In the manufacturing world, the discipline of tube bending may not always get its rightful share of the limelight, but its fundamental role in countless industries is indisputable. From automotive and aerospace to construction and furniture design, tube bending shapes everyday life.

AWC Industries, a company with a strong foothold in the manufacturing industry, has positioned itself as a premier source of state-of-the-art tube bending services. This blog aims to demystify the tube bending process, specifically focusing on the quality, precision, and innovations that AWC Industries brings.

The Basics of Tube Bending

Tube bending is a fabrication process in which tubes or pipes are shaped into specific forms for various industries. The method involves changing the tube’s structure without altering its volume. AWC Industries employs the most advanced technology and techniques in tube bending, resulting in products catering to a broad spectrum of applications.

Bending the tube without compromising its integrity is a delicate process that requires expertise and precision. Various techniques are used in tube bending, such as ram-style bending, rotary draw bending, roll bending, and more. Each technique has its merits and is chosen based on factors like the end product’s purpose, the tube’s material, and the desired bend radius.

Precision CNC Tube Bending at AWC Industries

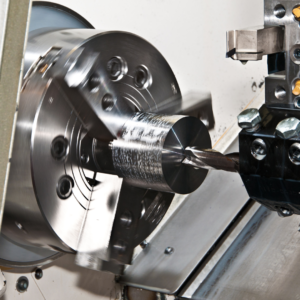

AWC Industries have set a new standard in tube bending with our precision CNC (Computer Numerically Controlled) tube bending services. Located in Illinois, we leverage this advanced technology to provide accurate, consistent, and efficient tube bending solutions.

The CNC tube bending process utilizes digitally created designs as a blueprint. These designs guide the bending machine’s operation, ensuring that the result matches the original concept as closely as possible. This process is efficient and reliable and significantly reduces production times.

AWC Industries’ Competitive Edge

Our unwavering commitment to quality and precision sets AWC Industries apart in the tube bending sector. We understand that every bend matters and that even the slightest deviation can lead to significant problems.

Our team of highly skilled professionals is trained in the latest tube bending techniques. We work relentlessly to ensure that every product that leaves the factory is of the highest quality, meeting or exceeding customer expectations.

Moreover, we are ISO 9001:2015 certified, which is a testament to our commitment to maintaining stringent standards of quality and consistency in our production processes.

Embracing Innovation

At AWC Industries, innovation is the lifeblood of our operations. By continuously staying ahead of the latest trends in tube bending technology, we can provide our customers with advanced, high-quality solutions that cater to a wide range of applications.

Our state-of-the-art CNC machines provide exceptional accuracy and repeatability, enabling us to offer consistent quality across large production runs. This level of precision is vital in industries where a slight variance can lead to drastic consequences.

Final Thoughts

Tube bending is a complex process requiring a delicate blend of technology, precision, and expertise. AWC Industries, with its cutting-edge facilities and unwavering commitment to quality, sets the standard for excellence in the field. Whether a simple bend or a complex, multi-faceted project, AWC Industries is the go-to expert for all tube bending needs.

If you’d like more information on Precision CNC Tube Bending by AWC Industries, contact us here today. We look forward to serving in 2023 and beyond.