The Essential Guide to Wire Guards

When it comes to protecting machinery, equipment, and workers, wire guards are indispensable. These versatile safety components are used across various industries to prevent accidents and help ensure smooth operations. In this blog, we’ll delve into what wire guards are, their key benefits, and why AWC Industries stands out as the leading custom manufacturer in the Chicagoland area.

What Are Wire Guards?

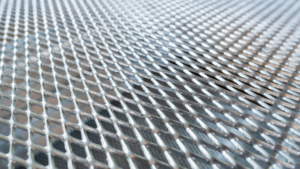

Wire guards are protective barriers made from metal wires, often fashioned into a mesh or grid pattern. Wire guards are designed to help safeguard machinery, equipment, and personnel by providing a robust yet flexible barrier that allows visibility and airflow while preventing access to hazardous areas. Wire guards are commonly used in industrial settings, including manufacturing plants, warehouses, and distribution centers.

Key Benefits of Wire Guards

- Safety: The primary function of wire guards is to help enhance safety by creating a barrier between dangerous machinery and workers. This helps prevent accidents and injuries caused by direct contact with moving parts or other hazards.

- Durability: Made from high-quality metal, wire guards are incredibly durable and can withstand harsh industrial environments. They offer long-lasting protection, reducing the need for frequent replacements.

- Versatility: Wire guards can be custom-made to fit various applications, from protecting machine parts to enclosing entire areas. Their design allows for easy modification and adaptability to specific needs.

- Visibility and Ventilation: The open design of wire guards helps ensure that machinery remains visible, allowing for easy monitoring and maintenance. Additionally, the mesh structure promotes ventilation, preventing the buildup of heat and debris.

- Cost-Effective: Wire guards are a cost-effective safety solution. Their durability and low maintenance requirements make them a wise investment for any industrial setting.

Applications of Wire Cage Guards

Each wire cage guard serves a unique purpose, safeguarding against vandalism, accidental damage, and theft while maintaining accessibility. Here are some common applications:

- Fire Alarms, Smoke Detectors, and Sprinklers: Protecting critical safety equipment with wire guards ensures uninterrupted functionality while prioritizing ease of access during emergencies.

- Clocks: Shielding clocks from potential damage not only preserves their longevity but also prevents unnecessary replacements, saving costs in the long run.

- Exit Signs: Maintaining the visibility and legibility of exit signs is crucial for emergency situations. Wire guards offer robust protection without obstructing their primary function.

- Bells, Speakers, and Alarms: Whether traditional bells or modern electronic alarms, wire guards ensure these vital components remain intact and operational.

- Thermostats: Preventing tampering or theft of thermostats is essential for maintaining comfortable environments. Wire guards strike the perfect balance between protection and accessibility.

- Emergency Lighting: Safeguarding emergency lighting fixtures with wire cage guards ensures they remain functional and ready to illuminate when needed most.

Why Choose AWC Industries for Custom Wire Guards?

Located in the heart of the Chicagoland area, AWC Industries is the go-to provider for custom wire guards. Here’s why:

- Expertise and Experience: With decades of experience in the industry, AWC Industries has honed its skills in manufacturing high-quality wire guards. Their team of professionals is adept at designing and producing custom solutions tailored to meet specific needs.

- State-of-the-Art Facilities: AWC Industries boasts state-of-the-art manufacturing facilities equipped with the latest technology. This enables them to produce wire guards with precision and efficiency, ensuring top-notch quality.

- Custom Solutions: At AWC Industries, customization is key. They understand that each client has unique requirements and are committed to delivering wire guards that fit perfectly. From design to fabrication, they work closely with clients to ensure complete satisfaction.

- Commitment to Quality: Quality is at the core of AWC Industries’ operations. They adhere to stringent quality control measures throughout the manufacturing process, ensuring that each wire guard meets the highest standards.

- Customer Service: AWC Industries prides itself on providing exceptional customer service. Their responsive and knowledgeable team is always ready to assist with any queries, offering support from initial consultation to post-installation.

- Competitive Pricing: Despite offering premium products and services, AWC Industries maintains competitive pricing. They strive to provide cost-effective solutions without compromising on quality.

Wire guards are essential for ensuring safety and efficiency in industrial environments. When it comes to custom wire guards, AWC Industries is the premier choice in the Chicagoland area. Their expertise, state-of-the-art facilities, commitment to quality, and exceptional customer service make them the best partner for all your wire guard needs. Trust AWC Industries to deliver the protection your equipment and personnel deserve.