What is Brass Tube Bending?

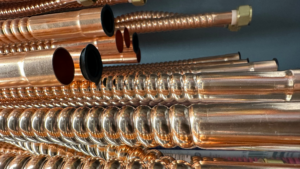

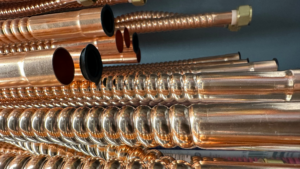

Brass tube bending is a specialized process within the broader field of metal fabrication. It involves shaping brass tubes into specific angles or curves without compromising the structural integrity of the material. This process is crucial in various industries, including automotive, plumbing, HVAC, and furniture manufacturing. Brass, known for its durability, resistance to corrosion, and aesthetic appeal, is an ideal material for these applications.

The Process of Brass Tube Bending

The process of brass tube bending can be intricate, requiring precise control and expert handling. Here are the main steps involved:

- Design and Planning: Before the actual bending begins, a detailed design is created. This includes specifying the dimensions, bend angles, and radii. Computer-aided design (CAD) software is often used to create accurate plans.

- Material Selection: The quality of the brass is critical. AWC Industries uses high-grade brass that meets industry standards to ensure the final product is both strong and visually appealing.

- Bending Techniques: Various techniques are employed depending on the complexity and requirements of the project. Common methods include rotary draw bending, roll bending, and mandrel bending. Each technique has its advantages in terms of precision and application.

- Quality Control: After bending, the tubes undergo rigorous quality checks. This ensures that the bends are accurate, the dimensions meet specifications, and there are no defects such as cracks or deformities.

Metal Fabrication at AWC Industries

Beyond brass tube bending, AWC Industries offers comprehensive metal fabrication services. Metal fabrication involves cutting, bending, and assembling metal structures from raw materials. It encompasses a wide range of processes including welding, machining, and forming.

Why AWC Industries Stands Out

- Expertise and Experience: With decades of experience in the industry, AWC Industries boasts a team of highly skilled professionals. Their expertise covers a wide range of materials and fabrication techniques, ensuring that they can handle any project, no matter how complex.

- State-of-the-Art Technology: AWC Industries invests in the latest technology and equipment. This not only enhances the precision and quality of their work but also allows them to tackle innovative and challenging projects.

- Commitment to Quality: Quality is at the heart of everything AWC Industries does. From the initial design phase to the final product, stringent quality control measures are in place to ensure the highest standards are met.

- Custom Solutions: AWC Industries understands that each project is unique. They offer customized solutions tailored to the specific needs and requirements of their clients. This flexibility ensures that customers receive exactly what they need, whether it’s a simple bend or a complex assembly.

- Customer Satisfaction: Building long-term relationships with clients is a key priority for AWC Industries. Their commitment to customer satisfaction is evident in their attention to detail, prompt service, and reliable support throughout the project lifecycle.

Applications of AWC Industries’ Expertise

The applications of brass tube bending and metal fabrication are vast. AWC Industries serves a diverse range of industries including:

- Automotive: From exhaust systems to chassis components, precision bending and fabrication are crucial in the automotive sector.

- HVAC: Efficient and reliable HVAC systems often require custom-fabricated components for optimal performance.

- Furniture: Aesthetic and functional furniture pieces benefit greatly from expertly bent and fabricated metal components.

- Plumbing: Durable and corrosion-resistant brass tubes are essential for high-quality plumbing systems.

AWC Industries is more than just a metal fabrication company; they are a partner in innovation and quality. Their expertise in brass tube bending, coupled with their comprehensive metal fabrication services, positions them as a leader in the industry. Whether you’re in need of precise components for a complex project or seeking a reliable partner for ongoing fabrication needs, AWC Industries is the go-to choice. Their dedication to excellence ensures that every project is completed to the highest standards, cementing their reputation as the best in the business.

Contact us today for more information and a fast, reliable quote. We look forward to working with you!