Precision in Every Cut: Sheet Metal Fabrication Services at AWC Industries

Sheet metal fabrication is a manufacturing process that transforms flat sheets of metal—like aluminum, stainless steel, and carbon steel—into custom parts and structures. This process includes cutting, bending, welding, and assembling components with high precision.

At AWC Industries, we bring decades of experience and innovation to every sheet metal project. Based in Chicago, we serve a wide range of industries—from food processing and HVAC to medical and OEMs—offering unmatched expertise, fast turnaround times, and personalized customer service.

Whether you’re developing a prototype or scaling up to mass production, AWC Industries is your trusted partner for sheet metal fabrication in Chicago and beyond.

Why Sheet Metal Fabrication Matters

Sheet metal fabrication is the backbone of many essential products and infrastructure systems. Its versatility and strength make it ideal for custom enclosures, brackets, panels, guards, and more.

Key benefits of fabricated sheet metal include:

- Durability: Resistant to corrosion and wear, ideal for demanding environments.

- Customizability: It is Perfect for tailored designs, intricate cuts, and complex bends.

- Efficiency: Fast production and scalability make it a cost-effective solution.

Whether you’re in aerospace, automotive, construction, or food manufacturing, quality sheet metal fabrication ensures performance and longevity.

AWC Industries: Leaders in Custom Sheet Metal Fabrication

At AWC Industries, we combine state-of-the-art equipment with experienced craftsmanship to provide high-quality custom sheet metal solutions. Our fabrication process ensures tight tolerances, smooth finishes, and consistent results from start to finish.

Our Sheet Metal Capabilities Include:

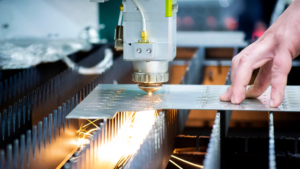

- Laser Cutting

- Punch Press Fabrication

- Forming and Bending

- MIG and TIG Welding

- Assembly and Finishing

- Prototyping to Production Runs

We handle a variety of metals, including:

- Stainless Steel

- Aluminum

- Galvanized Steel

- Cold Rolled Steel

- Copper and Brass

Each project is executed with precision and tailored to your exact specifications.

Our Process: From Design to Delivery

Our streamlined process ensures quality at every stage of your sheet metal fabrication project.

1. Design & Engineering Support

Bring us your CAD files or sketches, and we’ll help fine-tune your design for manufacturability, cost-efficiency, and structural integrity.

2. Material Selection

Choosing the right metal for your application is key. We help you evaluate strength, corrosion resistance, weight, and budget.

3. Cutting & Punching

Our CNC laser cutting and punch press capabilities ensure precise cuts with minimal waste. We can accommodate both intricate details and large production volumes.

4. Forming & Bending

Using CNC press brakes, we bend sheet metal into precise angles with tight tolerances. Our skilled operators ensure consistency across every part.

5. Welding & Assembly

Depending on your materials and project needs, we offer MIG and TIG welding. We can also provide spot welding and mechanical fastening.

6. Finishing & Inspection

Whether you need powder coating, plating, or polishing, we deliver parts that perform and look great. Every item undergoes rigorous quality checks before shipping.

Industries We Serve

Our fabrication work spans industries that demand reliability, precision, and fast delivery:

Food Processing

We manufacture stainless steel parts and guards that meet food safety standards—ideal for conveyors, mixers, and sanitation equipment.

HVAC

We produce durable ductwork, brackets, and custom sheet metal parts for heating, ventilation, and air conditioning systems.

Medical & Laboratory

Precision is everything in healthcare. We fabricate equipment housings, frames, and structural components to meet strict regulatory standards.

Industrial & Manufacturing

We help keep industrial equipment safe and productive from machinery guards to OEM components.

Automotive & Transportation

We work with manufacturers to create durable, lightweight parts that stand up to vibration, heat, and wear.

Why Choose AWC Industries?

Plenty of fabricators are out there, but few can match AWC Industries in terms of customer service, quality, and speed.

End-to-End Service

From initial design to final delivery, we handle every step in-house to ensure faster lead times and better quality control.

Engineering Expertise

Need help optimizing your design? Our experienced engineers and fabricators collaborate with you to find the most efficient path from concept to production.

Advanced Equipment

We invest in the latest CNC laser cutters, press brakes, welders, and finishing tools to provide consistent, high-quality parts.

Quick Turnaround

Your time is valuable. We work efficiently to meet tight deadlines without compromising on quality.

Made in Chicago

Proudly serving the Midwest and beyond, we offer reliable American manufacturing with personalized attention.

Common Sheet Metal Fabrication Projects

If you can sketch it, we can fabricate it. We create a wide variety of custom sheet metal parts and assemblies, including:

- Enclosures and cabinets

- Machine guards

- Ventilation panels

- Chassis and frames

- Mounting brackets

- Electrical panels

- Decorative and architectural metalwork

Sustainable and Cost-Efficient Manufacturing

As a second-generation family-owned business now welcoming a third generation, AWC Industries is built on long-term commitment and hands-on expertise. The three brothers at the helm remain actively involved in every aspect of the company, from sales and estimating to engineering, production, and quality control.

Our dedication extends beyond customer service to responsible manufacturing. We take pride in implementing sustainable practices that benefit both your bottom line and the environment:

- Material optimization to reduce waste

- Energy-efficient processes in cutting and welding

- Recycling scrap metal and raw materials whenever possible

At AWC Industries, we help you lower costs and reduce your environmental footprint—without ever compromising on quality.

How to Get a Quote for Sheet Metal Fabrication

Ready to start your project?

We make it easy to request a quote. Just provide your:

- Project specs or CAD file

- Desired materials

- Quantity and timeline

- Any finishing requirements

Our team will follow up with a detailed estimate and timeline, often within 24-48 hours. Need a quote? See here.

Final Thoughts: Let’s Build Something Great

At AWC Industries, sheet metal fabrication isn’t just about bending and welding—it’s about solving problems, improving products, and delivering on your vision. Whether you need a single custom bracket or thousands of components, we’re here to make it happen—with precision, speed, and reliability.

Partner with AWC Industries—where quality meets craftsmanship. Call us today or request a custom quote online at awcindustries.com

Frequently Asked Questions (FAQs)

What is the minimum order quantity for custom sheet metal fabrication?

We work on both small prototypes and large-scale production runs—no project is too big or small.

What materials do you work with most?

Stainless steel, aluminum, cold rolled steel, and galvanized steel are among our most commonly used materials.

How long does it take to complete a fabrication order?

Turnaround time depends on project complexity and volume. We strive for fast, on-time delivery for every job.

Can you help with design and prototyping?

Absolutely. Our team offers engineering support and prototyping services to ensure your design is ready for production.

What industries do you specialize in?

Food processing, HVAC, medical/lab equipment, industrial manufacturing, and more.