AWC Industries takes immense pride in its impeccable standing within the realm of tube fabrication and tube bending. We extend our Precision tube and Pipe Bending services to a wide array of industries, encompassing construction, agriculture, food and beverage equipment, and beyond. Moreover, our strategic location in Illinois equips us with the capacity to swiftly and securely ship your products to any destination within the United States.

Our goal at AWC Industries is to provide our clients with the highest level of customer satisfaction by supplying fast, quality tube bending, wire forming and metal services to help you meet your production needs and get your products out to your customers.

Let’s dive into the fine details. What is tube bending? How does it work? Who can do it? How long does it take? One misconception that people may have is that tube bending is a fairly quick and simple process. This could not be farther from the truth. There are many “tools” and honed skills that need to be used in order to bend a tube properly…

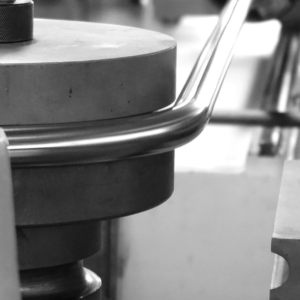

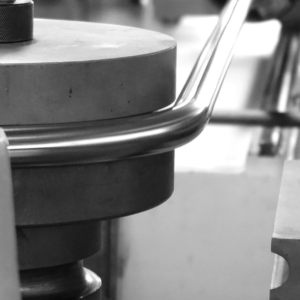

Tube Bending: How We Do It

Tube Bending is an important step in the process of manufacturing industrial pipes and tubing, which serve a vital role in both construction and the transportation of materials. Most bent pipes and tubes function as structural components or as “passageway” units that facilitate the transfer of substances.

Tube bending is a craft often required to bend metal tubes and bring them to customized shapes for performing a number of important functions. They are required by various types of industries, such as aerospace, construction, military and furniture sectors.

We at AWC Industries specialize in high end metal bending, fabricating and finishing services. We offer tube bending services for ferrous as well as non-ferrous substances such as aluminum, brass, copper, steel and stainless steel. Our state of the art CNC tube bending and fabricating facilities can produce the highest quality finished goods and we can bend and fabricate metal tubes of up to 3 inch diameter.

As a tube or pipe is being bent, the exterior wall at the point of the bend begins to stretch and thin out. Simultaneously, the corresponding interior segment of the workpiece becomes thicker and more compressed. Controlling these degrees of physical deformation is important for creating a smooth rounded bend. Thick walled tubes bent at a wide radius are likely to have a relatively low degree of deformation, but thinner tubes may not.

Midwest Tube Bending by AWC Industries

When you get in touch with us, we will try and understand your specific requirements and make sure that your project priorities are duly met with. By working with us, you can be rest assured that your technical projects will achieve the highest zenith of success. Our technical team can provide you with the best expertise in the industry, and you can expect your finished goods at the earliest turnaround time.

Some of our most common products include furniture frames, dipstick tubes, tubular legs, lifting handles, display racks, spreader frames, pull handles as well as bleacher end rails and we serve a number of industries, such as agricultural, military, medical, automotive and aerospace sectors. At AWC Industries, our prime goal is to provide our clients with the best range of finished goods that will serve their purposes, and it is this unflinching insistence on quality and good customer service that has made us industry leaders.

Let the experts at AWC Industries take care of your tube bending needs. Contact us today for a quote and to find out more on why we’re the number one tube bending specialists across Illinois.